Characteristic Advantages

1.Precise size customization

Cutting according to customer drawings or requirements, with high precision, can be controlled within ± 0.1mm;

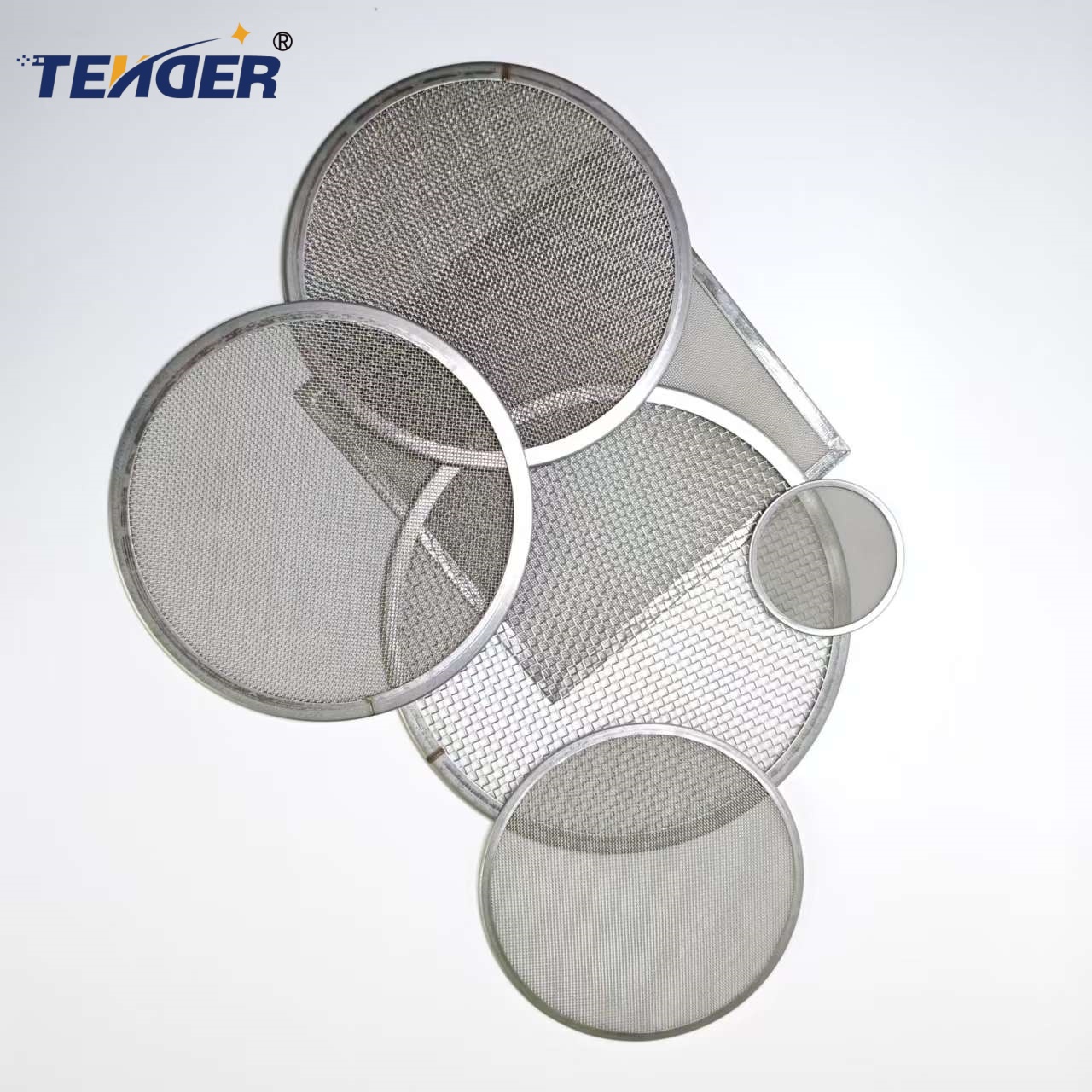

Can be made into complex shapes such as square, circular, irregular, with edge holes, and with ears;

Support batch size consistency, convenient for automated assembly.

2. Multiple material options to adapt to different environments

Provide a variety of metal materials (stainless steel, copper, titanium, nickel, iron chromium aluminum, etc.);

Can cope with special environments such as high temperature, high corrosiveness, strong acidity and alkalinity, food hygiene level, and conductivity;

Materials can be selected in accordance with FDA, RoHS and other certified specifications.

3. Multiple types of mesh, covering a wide range of filtering accuracy

Available in plain weave, twill weave, dense weave, mat weave, etc;

Filter pore sizes range from 1 micron to several millimeters;

Single layer or multi-layer composite mesh can be customized to meet different needs from microfiltration to coarse filtration.

4. Flexible edge processing methods

Can be used for cutting burrs, edging (stainless steel frame or aluminum ring), spot welding fixation, curling, etc;

Helps to improve safety, prevent shedding, and enhance service life;

Better aesthetics, suitable for terminal product assembly or exposed appearance occasions.

5. Diverse processing methods to adapt to industrial production

Adopting efficient processing techniques such as CNC cutting, laser cutting, waterjet cutting, and punching molds;

Can achieve small batch customization or large-scale standardized production;

High precision, fast efficiency, and flexible delivery time.

6. Strong adaptability and wide compatibility with various devices

Can be directly applied as a filtering element in liquid filters, air purifiers, fuel systems, etc;

Can be used as structural components such as mold filters, battery separators, electromagnetic shielding layers, etc;

Easy to replace, assemble, and maintain, convenient for after-sales management.

Common Specifications

Item | Description | |

Size Range | Custom sizes: e.g., 50×50mm, 100×100mm, Ø80mm, 200×300mm, etc. | |

Thickness | Based on mesh type or layer count, typically 0.05mm – 1mm | |

Filtration Precision | From 1 micron to several millimeters, depending on mesh type | |

Layer Options | Single-layer or multi-layer (can be welded or spot-welded) | |

Surface Treatment | Cleaning, acid-washing, electrolytic polishing, ultrasonic degreasing, edge-wrapping | |

Packaging | Single packed, stacked in bulk, blister box, anti-dust bag, customized on request | |

Shape | Application | |

Square / Rectangular | Layered filtration, frame-mounted filters, equipment filters | |

Round / Disc | Filter cartridges, mold vents, pipeline end filters | |

Oval / Ring | Oil filtration, hydraulic system elements | |

Custom / Irregular | Tailored to equipment drawings or installation structures | |

Material | Features | |

Stainless Steel (304, 316, 316L) | Corrosion-resistant, high-temperature tolerance, suitable for most industrial filtration applications | |

Brass / Copper | Excellent electrical conductivity, non-magnetic, ideal for ESD-sensitive and electrical applications | |

Nickel Mesh | Acid and alkali resistant, high heat tolerance, suitable for batteries and electrolytic systems | |

FeCrAl Mesh | High temperature oxidation resistance, used in heating and thermal filtration | |

Titanium Mesh | Lightweight, corrosion-resistant, used in marine and medical industries | |

Duplex Steel / Hastelloy / Inconel | For harsh environments requiring extreme corrosion, pressure, or temperature resistance |

Application Area

Liquid Filtration: Water treatment, beverages, chemical, pharmaceutical industries

Gas Filtration: Air purification, combustion systems, respirators

Solid Separation: Particle separation, debris filtering

Equipment Protection: Fan guards, intake mesh, mechanical barriers

Electronics: EMI shielding, vent protection, dust screens

Injection Molding: Mold screens, anti-blocking filters

New Energy: Fuel cells, battery electrolyte filtration

Our mesh type filter is designed to meet a variety of filtration needs across industrial and domestic applications. Whether used in HVAC systems, kitchen range hoods, or manufacturing environments, the wire mesh type filter offers flexible functionality with customizable filter cloth micron size options. You can select micron ratings to suit your specific dust, air, or grease separation requirements.

One of the key advantages of this product is its adaptability. If you're wondering how to cut hardware mesh or how to cut mesh wire, this filter is manufactured to be easily trimmed with wire cutters or tin snips without fraying or deforming. This feature allows for seamless installation into custom-sized housings or confined spaces, making it a favorite for both DIY and professional use.

Constructed with premium materials such as aluminium filter mesh, this filter is corrosion-resistant, lightweight, and highly durable. It is reusable, washable, and maintains its shape even after extended use. For kitchen applications, the aluminium grease filter mesh variant is specially designed to trap oil and airborne particles efficiently while allowing airflow.

Whether you're looking for a robust air filter or a flexible grease-trapping solution, this mesh type filter delivers superior performance and long-term value.

The aluminium grease filter mesh is a lightweight, corrosion-resistant solution designed for kitchens, HVAC systems, and industrial air filtration. Built with high-grade aluminium filter mesh, this product offers optimal airflow while effectively trapping airborne grease, dust, and other contaminants.

A key advantage is its customizable filter cloth micron size, which ensures precise filtration for different applications. Whether you’re managing oil mist in a commercial kitchen or improving air quality in a workshop, choosing the right micron rating helps increase system efficiency and reduce cleaning cycles.

This wire mesh type filter is also highly user-friendly. If you’ve ever searched for how to cut hardware mesh or how to cut mesh wire, you’ll appreciate the mesh's easy-to-cut structure. It can be trimmed with household tools like wire cutters or metal shears, allowing you to fit it perfectly into any filter frame or hood system.

The mesh type filter is reusable and washable, offering excellent value over disposable filters. Its interwoven wire structure maintains shape and performance through multiple cleanings and installations. In high-heat or oily environments, this aluminium grease filter mesh retains its filtration properties without corroding or clogging.

For reliable, customizable filtration that’s easy to handle and cost-effective, our aluminium filter mesh range is a smart choice. Custom sizes, micron ratings, and quantities are available to suit all commercial and residential needs.

Please leave us a message and we will get back to you shortly.